Can Hydraulic Cylinders Be Repaired?

Hydraulic cylinders are both powerful and reliable, but can also break down or wear out over time. Seal leakage, corrosion, and piston damage are some of the most common issues that you may experience with your hydraulic cylinders. Thankfully, most cylinders can undergo hydraulic cylinder repair.

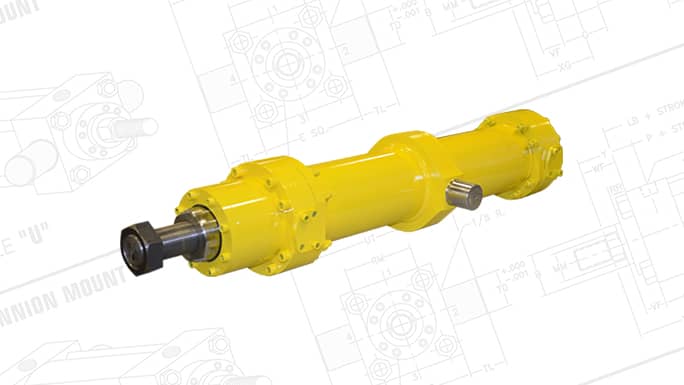

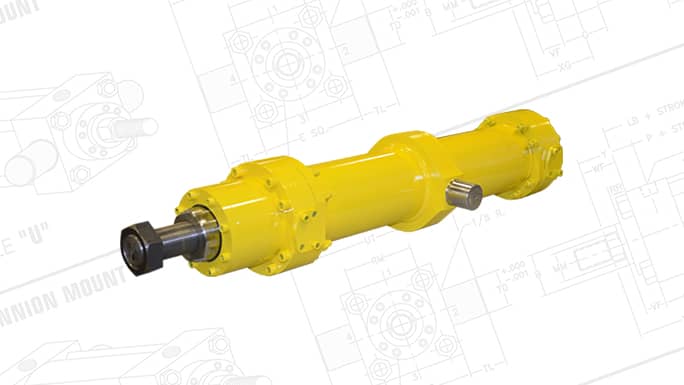

Hydraulic cylinders are simple machines that apply force in a linear direction. They are composed of a metal tube, a piston with an attached rod, and mounting brackets.

There are two types of hydraulic cylinders: single-acting and double-acting.

Single-acting hydraulic cylinders push the rod in one direction. When the rod moves back in the other direction, hydraulic pressure drops. Double-acting cylinders work differently, as they exert hydraulic pressure in both directions. Both types may require hydraulic cylinder repair in case of failure.

Hydraulic cylinders can be repaired, but you should never attempt these repairs on your own. Working with a trained technician will ensure fewer mistakes and a faster turnaround time. Although hydraulic cylinders have a simple design, you must be familiar with them in order to efficiently repair them. When a technician performs hydraulic cylinder repairs, they take the entire mechanism apart and reassemble to find the root cause of the issue.

There are several common points of hydraulic cylinder failure. These include the piston, rod, seals, and head.

The pistons in hydraulic cylinders are one of the most common points of failure. This is especially true in light-duty applications. The pistons used in light-duty applications are often made from aluminum, which wears out much more quickly than the steel used in heavy-duty applications.

When checking pistons for failure, technicians will often measure the diameter of the piston. The piston’s diameter in relation to the bore directly affects the amount of hydraulic pressure that the piston is able to deliver. If there are issues with your piston’s measurements, it will need to be replaced, along with any wear band that is installed.

Rods are perhaps the most likely culprit of a hydraulic cylinder failure. Rods often develop small cracks after long periods of heavy use. A technician will use a special dye to check for cracks in the rod.

Bent rods commonly cause hydraulic cylinder failures. A rod only needs to be bent very slightly for the cylinder to fail. One of the easiest ways to check for a bent rod is to inspect the chrome finish. If it is bright and shiny on one side, but worn off on the other, the rod is bent. Thankfully, bent rods can often be repaired by straightening in a press.

There are seals on both the piston and the rod of a hydraulic cylinder. If these seals leak, the cylinder will not be as powerful. Additionally, all of the oil will eventually leak out and the cylinder will fail. Unfortunately, damaged seals are often signs of more serious problems. While the seals themselves should certainly be replaced, the piston and rod should also be inspected.

A piston seal failure often indicates that the barrel has become distorted. Sometimes, the barrel is the only thing that needs to be replaced, but sometimes a distorted barrel is often caused by a problem with the piston. If this is the case, the entire cylinder must be replaced.

If the rod seal has failed, the most likely cause is a bent rod. As previously mentioned, bent rods can often be fixed in a press. A rod seal failure could also be caused by a worn guide bush. A worn guide bush can be quickly and easily replaced by a qualified technician.

It is fairly rare for the head to be the cause of a hydraulic cylinder failure, but it can happen. The head connects the rod to the piston. The most common type of head failure occurs when the head is distorted so that it is bigger than the rod. The head should not measure more than .004 of an inch bigger in diameter than the rod. If it does, it must be replaced, or a bronze bush must be added.

It is also possible for the head’s seal grooves to be distorted so that they are significantly bigger than the rod. If the lands of the seal grooves measure more than .016 of an inch larger in diameter than the rod, the head must be replaced.

If your hydraulic cylinder has failed, it is important to find the right hydraulic cylinder repair company. Yates Cylinders has been a leading name in hydraulic cylinder repair since 1972, and offers 24/7 emergency services. Trying to repair a hydraulic cylinder yourself can be ineffective and dangerous. It is safer and more efficient to turn to us—we have the experience needed to get the job done right.

Click here to learn more about our hydraulic cylinder repair services, or contact us today at (877) 909-2752 to request emergency repairs.