Since 1972 Yates has been the top hydraulic cylinder seal kits suppliers in the United States. Our kits are manufactured to fit different sizes of rods.

Save time (and frustration) with hydraulic cylinder seal kits. When you use these kits, you can easily repair your hydraulic cylinders on your own.

Because a well working seal is crucial to the efficiency and speed of your machine, you do not want to wait until your machine malfunctions to repair the seal. Some of the types of seal kits we supply include:

Before we get into what a hydraulic cylinder seal kit is, it’s important for you to know what a hydraulic cylinder seal is.

Hydraulic cylinders have seals between many different components. These seals keep out liquid and solid contaminants. These contaminants can damage components of the hydraulic cylinder. Seals also help maintain hydraulic pressure, which ensures that the cylinder can keep operating powerfully. If a seal fails and a leak occurs, the hydraulic pressure will gradually decrease.

The seals in hydraulic cylinders are durable and last for a long time. However, they can become damaged after heavy use. When a cylinder is damaged, hydraulic fluid leaks out and contaminates the cylinder. If this happens to your cylinder, you don’t always have to take it into a repair shop. Instead, you may simply need to install a hydraulic cylinder seal kit.

There are many types of hydraulic cylinder seal kits. No matter the type, the purpose of these kits remains the same: to stop leaks by repairing the seal.

Before installing any kit, you need to look through the types of seal kits and find the one that suits your application.

Seals are commonly used in the hydraulics industry. The main task of a hydraulic seal is to keep hydraulic fluids flowing while preventing solid or liquid contaminants from entering the machine. The seal also helps to maintain the hydraulic pressure of the unit. These tasks require different seal designs and configurations. Occasionally, seals need to be repaired using hydraulic cylinder seal kits.

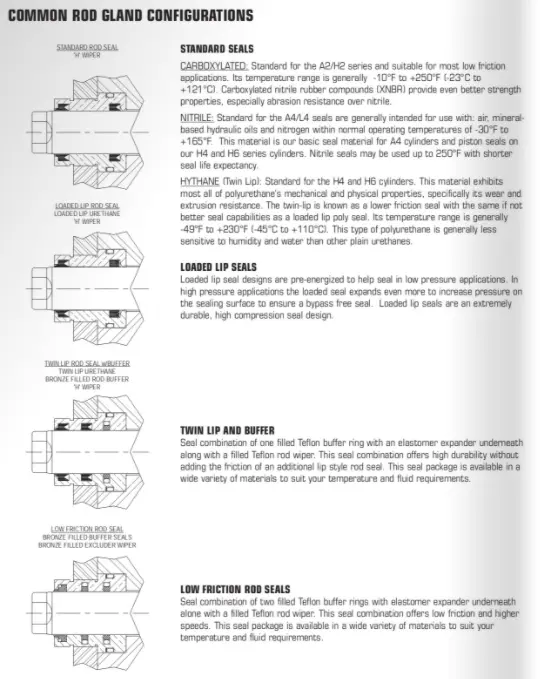

There are several types of seal kits available, including standard seals, loaded lip seals, fluorocarbon seals, cast-iron piston rings, and low-friction seals.

Most applications usually only require a standard seal kit, which is made out of nitrile, and should be used in air and mineral-based oils.

One of the most common specialty seal kits is the loaded lip seal. This kit is best for low-pressure applications.

A fluorocarbon seal is better for high-pressure applications. Cylinders used in many applications may be able to benefit from low-friction seals. These seals are carefully engineered to create as little friction as possible without allowing leaks to spring up.

If you have a high-speed and high-temperature application like those often seen in the construction industry, you may need a heavy-duty cast-iron piston ring. These rings are so durable that they are often used for heave shock applications. However, you should keep in mind that cast-iron piston rings do not create as tight of a seal as nitrile or urethane seals. They compensate for this by being deeper and wider than a standard seal.

Using a seal kit has several benefits over the alternative, which is taking your hydraulic cylinder to a specialty shop and getting it repaired. First, if you use a seal kit, as mentioned previously, you won’t need to take your machine to the shop. Installing a seal is fairly easy with the right equipment. Seal kits are designed to be installed quickly and easily by the people who operate the machine, not by professional mechanics.

The ease of installation is only one of the benefits of using a seal kit. You will also be able to save a great deal of money by using a seal kit. Additionally, you will save time, as your operation will not have to be put on hold while your hydraulic cylinder gets repaired.

As we noted earlier, the standard seal kit is perfect for the vast majority of applications. However, if you have a low-pressure application, you should use a loaded lip seal. With high-pressure applications, you should use a fluorocarbon seal. If you have an extremely high-speed and high-temperature application, you should consider a cast-iron piston ring.

Yates Industries is a leading manufacturer of hydraulic cylinders. We’ve been serving clients in the United States since 1972, and take pride in our stellar reputation. If you need to repair your hydraulic cylinder seal, we’re here to help. We offer competitively priced hydraulic cylinder repair services, and also sell our own seal kits. Whether you need us to perform repairs for you, or want to repair them yourself, we have you covered.

Call (586) 257-2895, or fill out our online form today to request a quote on cylinder repairs or hydraulic cylinder seal kits.

Fill out the form below to get in touch with the leading hydraulic cylinder seal kits suppliers in the USA. A Yates Cylinders associate will contact you within one business day.