How Automation & Smart Manufacturing Are Changing Hydraulic Cylinder Demands

As the industry changes, so should the manufacturers. Learn how hydraulic cylinder manufacturers are responding to increasing automation demands.

As the industry changes, so should the manufacturers. Learn how hydraulic cylinder manufacturers are responding to increasing automation demands.

Industry 4.0, the fourth industrial revolution, is about manufacturers using data to optimize and improve their operations. This revolution will lead to higher productivity, better products, and less waste, but only if the machine builders have the hardware to make it all happen.

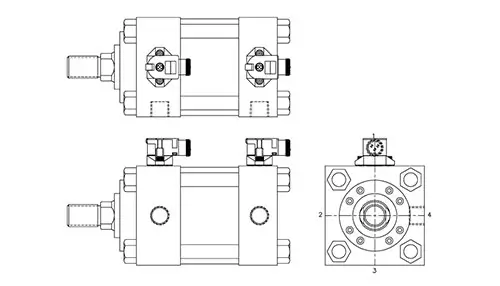

Industry 4.0 starts with smart devices. That is, sensors and actuators that can measure and communicate data. In the case of hydraulic cylinders, that entails integrating sensors for measuring position and speed, not just at end points or mid-stroke, but continuously and in real-time to allow for faster, more precise operation, better integration capabilities, predictive maintenance, increased durability, and less downtime.

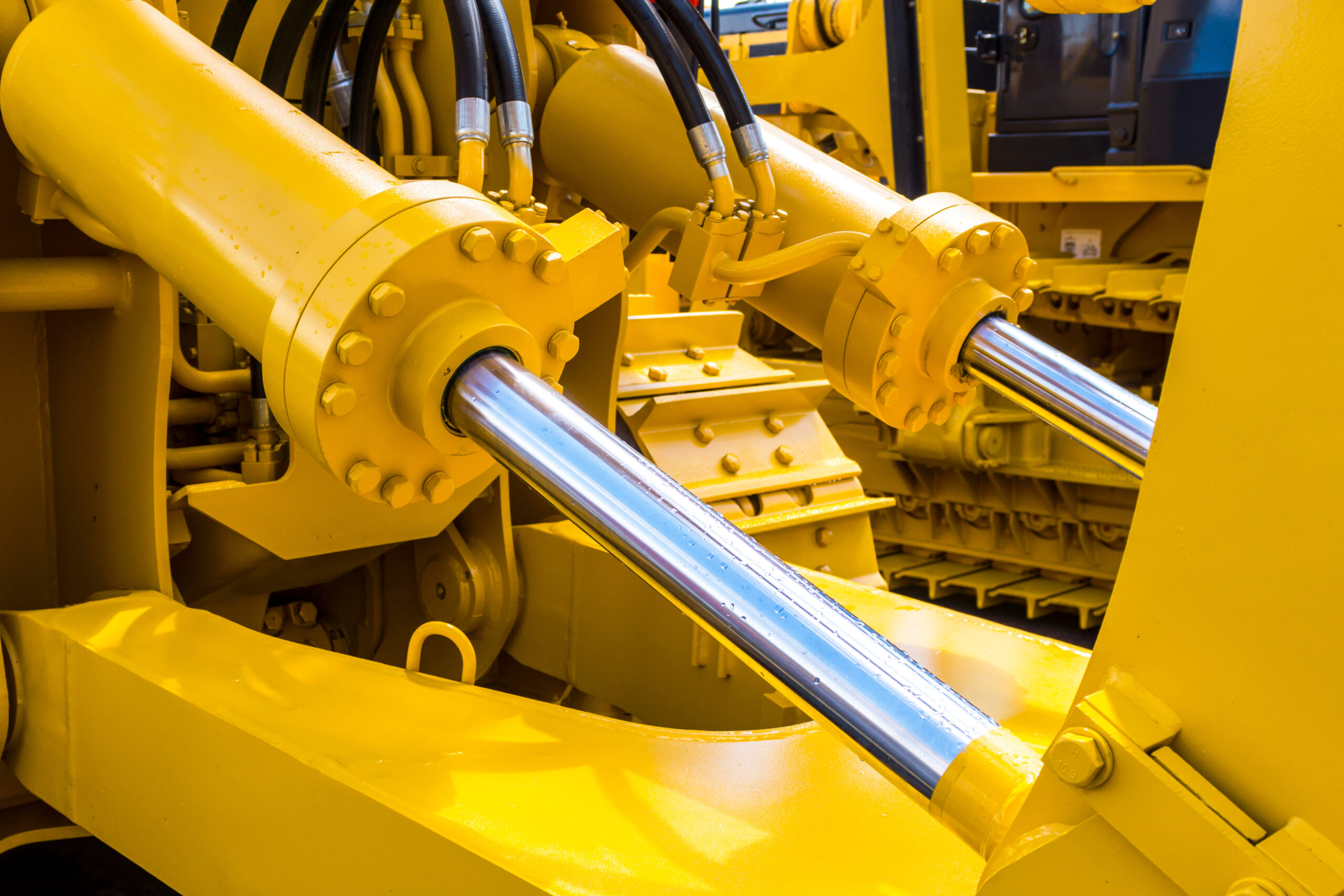

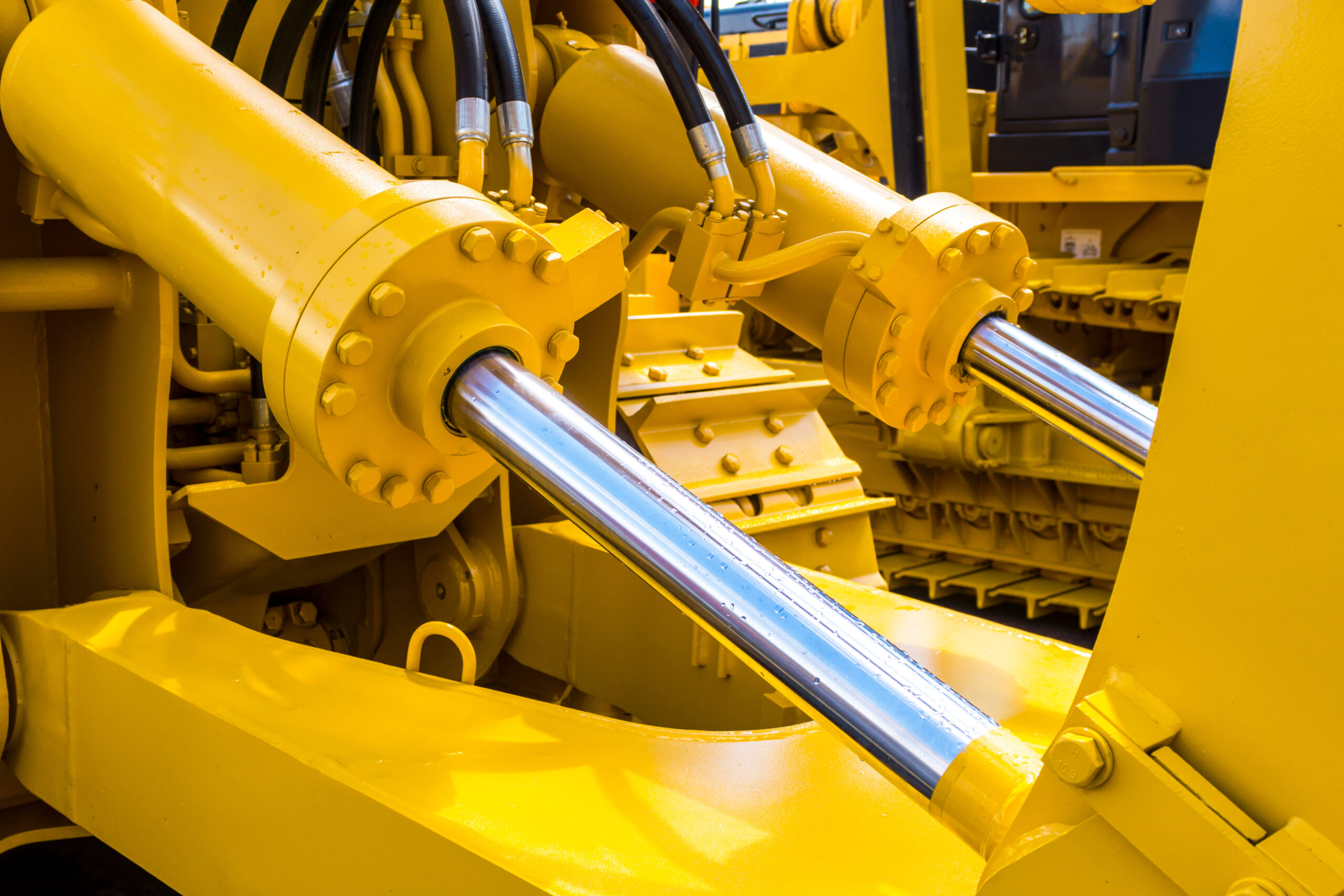

Before manufacturers began automating their operations, hydraulic cylinders were heavy-duty tools that were either on or off and required manual supervision.

As the industry automated, cylinders required more sophistication and control, so sensors began to appear, and pumps were integrated with control systems. This enabled more precise, unattended operation, but also increased the impact of any problems, such as rough motion and poor reliability.

Today, every manufacturer wants to increase productivity, improve quality, and reduce unplanned machine stoppages on their automated lines. That means running machines faster, so cycle times are shorter, increasing accuracy for better quality, and preventing breakdowns.

One key demand hydraulic cylinder manufacturers must adapt to is integration with smart systems, or how to transfer captured data out to other systems. Solutions include using PLCs, SCADA, and computerized maintenance management systems. Historically, this was done with serial communication, but today, wired systems like EtherNet/IP and Profinet, plus Wi-Fi and even cellular technologies, play ever greater roles.

The other key demand is greater wear resistance and reliability in high-duty/continuous motion applications, such as cutting, forming, and pressing.

Achieving higher unit loads and faster, smoother operation requires upgrades in bearings and seals, and in rod and cylinder materials. Modern seals use materials like PTFE and FKM for longer life, improved fluid resistance, and better load handling. Cylinder manufacturers are also evaluating better quality materials and newer coatings. Alloys are more highly specified, surface finishes are better controlled than ever, and coatings like polymers, ceramics, and even nano-coatings are all being investigated.

From the sensor perspective, teams are exploring industrial automation in hydraulic cylinder design, searching for smaller, smarter, yet more accurate and more reliable sensors for measuring properties like speed and vibration, then working out how to integrate them into their cylinders.

For many specialized industrial automation applications, custom cylinder engineering can be the most cost-effective approach. This is especially true for space-constrained applications, such as those found on many automated lines. This way, sensors are installed exactly where needed, with the preferred communications formats and cabling.

As expectations keep rising in the manufacturing sector, many off-the-shelf cylinders will not provide the desired performance and integration capabilities. Many will be too big, while others will lack the specific characteristics needed to optimize performance in a specific task or application.

These problems are addressed by carefully choosing a partner to work with for your smart cylinder requirements. While advanced design and testing capabilities are essential, they are far from all that is needed. The right partner should understand what you’re trying to achieve with higher levels of intelligence and control. They should also be familiar with and experienced in the technologies involved.

More importantly, though, they should demonstrate a willingness to build a long-term relationship with ongoing support. Only a business willing to step up in this way should be considered as a true partner for the future.

Smart manufacturing is the future, and builders of equipment and machinery are stepping up their efforts to provide the necessary services and capabilities. These demands also extend to the companies that design and build hydraulic cylinders—the components responsible for moving, processing, and holding in countless operations.

At Yates Cylinders, we understand the evolving challenges of automated production lines, and we’ve taken steps to ensure we can deliver the custom design services you need. If you’re engineering smart equipment, a conversation with one of our engineers will show you what’s possible with a modern hydraulic cylinder. Contact us today to get the process started.