What Is a Hydraulic Cylinder?

Hydraulic cylinders are heavily relied upon in nearly every industry. Learn more about what they do, how they work, and the different types.

Hydraulic cylinders are heavily relied upon in nearly every industry. Learn more about what they do, how they work, and the different types.

Hydraulic cylinders, or hydraulic actuators, generate mechanical force in a linear motion. They help press, pull, push, or lift heavy objects, and are used extensively in many industries, including manufacturing, construction, civil engineering, and aviation.

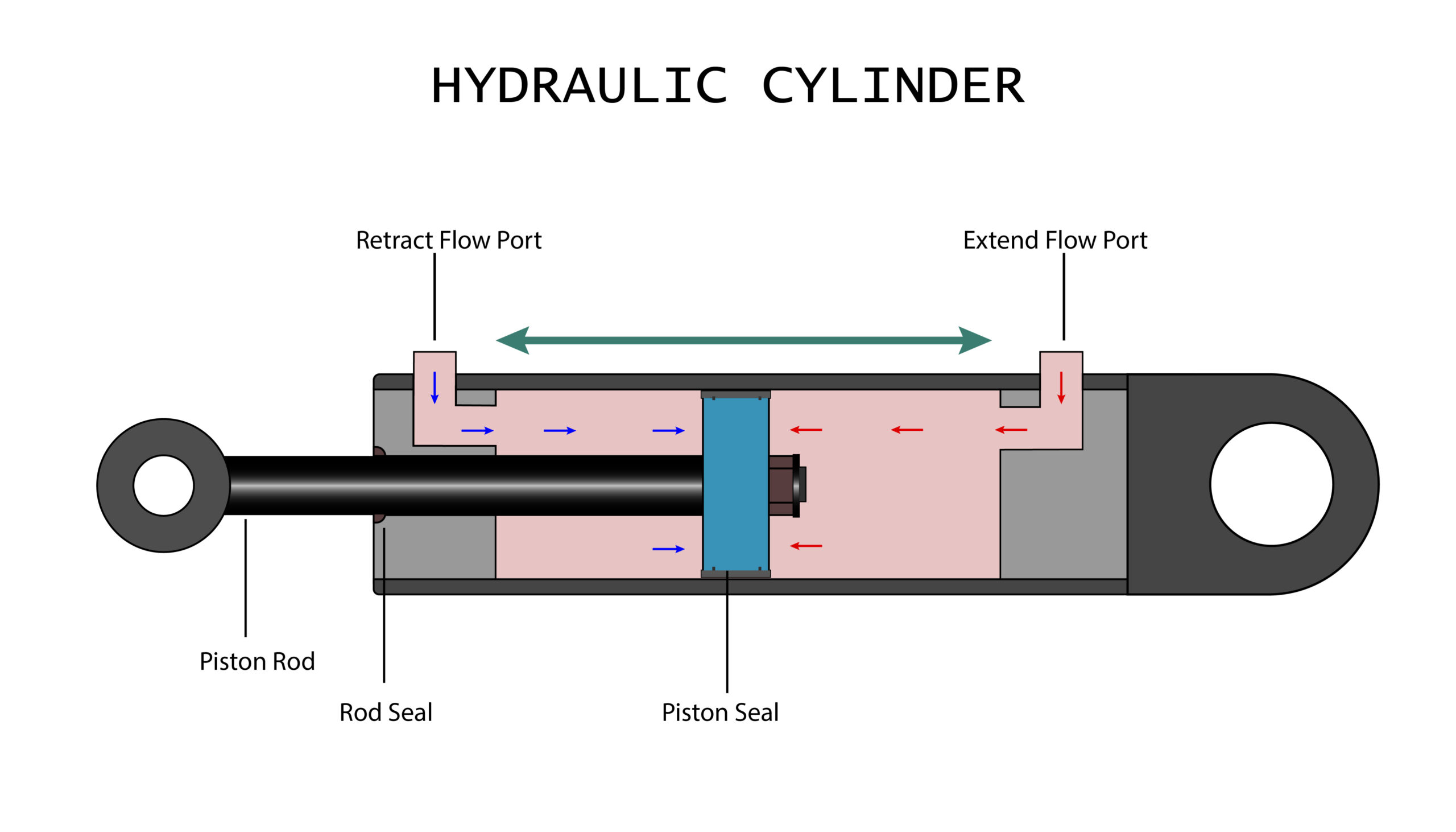

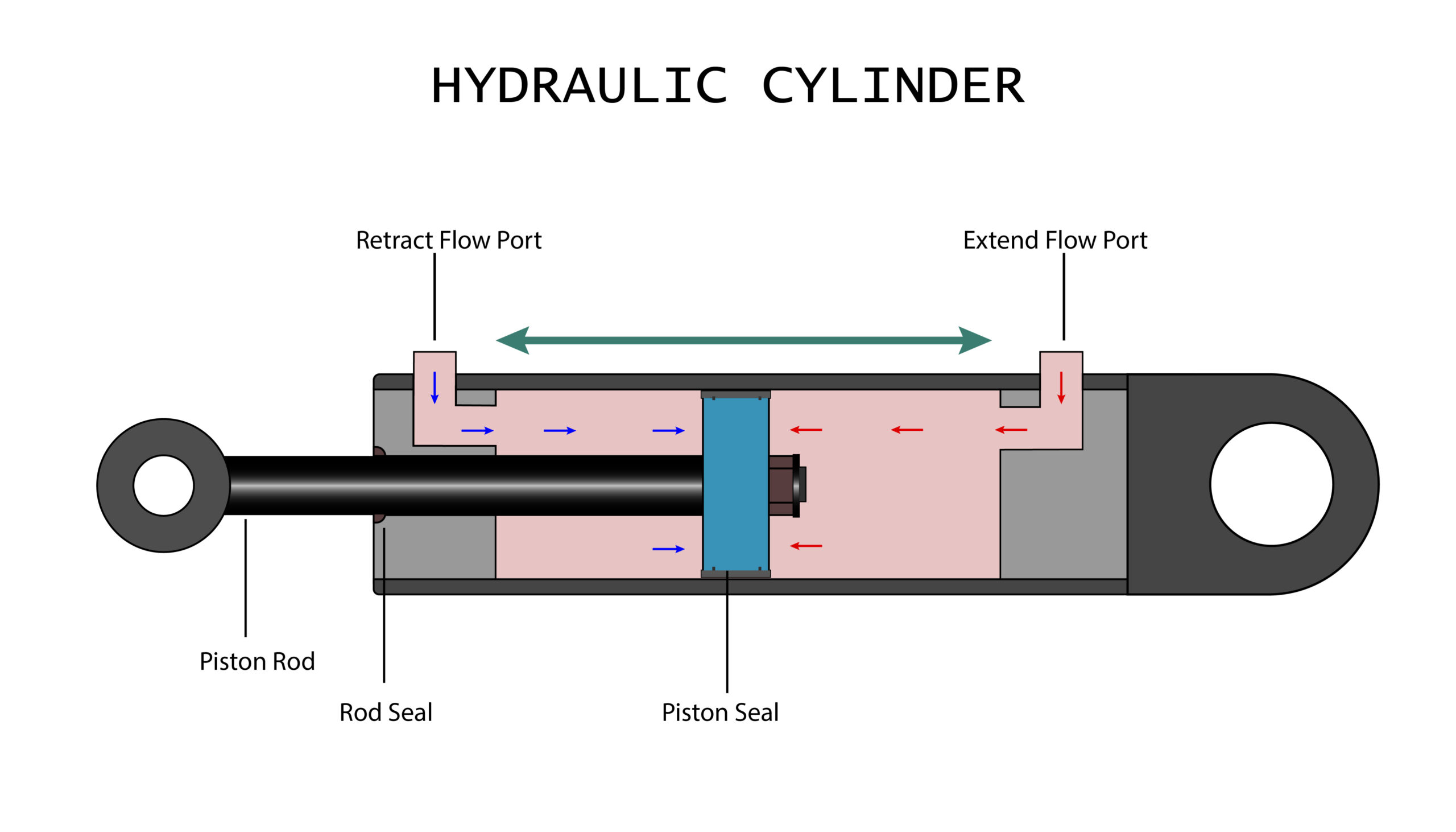

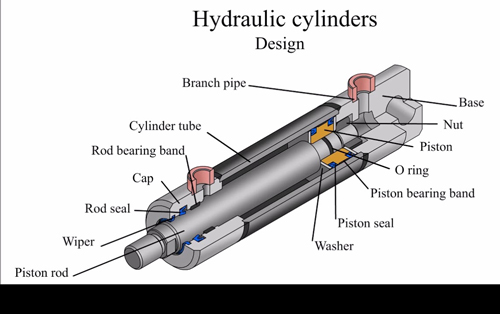

A hydraulic cylinder consists of several components (which we’ll break down in the next section) that work together to push pressurized hydraulic fluid into one side of the cylinder against the piston surface. Since liquids are incompressible, the pressure turns into a mechanical force, which moves the piston linearly within the cylinder, extending or retracting the piston rod.

If you want to get more technical, hydraulic actuators operate on the basis of Pascal’s Principle of fluid mechanics. In the 17th century, Blaise Pascal discovered that any change in pressure in hydraulic fluid results in the equal distribution of energy in every direction in the fluid chamber.

Pascal also discovered that the pressure in a fluid chamber equals the force applied divided by the area of the chamber. This formula, P=F/A, is the foundation for industrial machinery worldwide.

There is a wide variety of hydraulic cylinder configurations, including single-acting and double-acting. However, all cylinders contain the same basic components:

Single-acting hydraulic cylinders, also called push cylinders, produce power when hydraulic fluid enters a single port and flows into the cylinder, causing the cylinder to retract. They are called “single-acting” because they feature a single-acting piston that moves in one direction and requires a motor or spring to reset its position.

In double-acting hydraulic cylinder models, fluid moves into one port and exits through a second port, forcing the cylinder to retract and extend. With two pressurized chambers, double-acting pistons do not require a spring or motor to operate.

In heavy equipment like cranes, telescopic cylinders use a series of single-acting cylinders. When one cylinder retracts, it transfers force to the next cylinder.

A tandem cylinder has two separate barrels connected by the piston rods, allowing it to achieve a significant degree of force in a small area. Tandem cylinders can be combined in stages to provide more power.

Tie rod cylinder features external threaded rods that “tie” the cylinder together. They work very similarly to double-acting cylinders, except that the rods are tensioned to contain the internal pressure forces. Tie rods are easy to maintain because the end caps can be removed without causing downtime.

Welded, or mill-type, cylinders are used in heavy-duty applications where strength is critical. As the name suggests, they have a welded construction (the barrel is welded to the head and cap) but function similarly to a double-acting cylinder. They’re not as easy to maintain as a tie rod because the assembly is permanent.

Ram cylinders are only used in applications requiring a very high force with limited space. They function similarly to single-acting cylinders, where retraction relies on external forces. In a ram design, the hydraulic fluid enters through the single port and acts against the cross-sectional area of the ram.

Hydraulic linear actuators are used in countless applications in every corner of the globe. You can find them in:

Yates Industries is an industry-leading manufacturer and supplier of tie-rod, welded, and mill-duty hydraulic cylinders. Visit our website to learn more about our products or check out our blog for more resources.